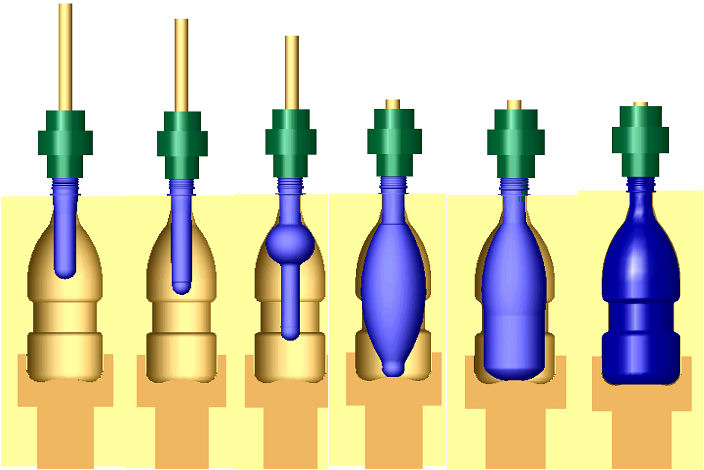

Stretch blowmoulding

In the stretch blow moulding (SBM) process, the plastic is first moulded into a preform using the injection moulding process. These preforms are produced with the necks of the bottles, including threads (the finish) on one end. These preforms are packaged, and fed later (after cooling) into a reheat stretch blow moulding machine. In the SBM process, the preforms are heated (typically using infra-red heaters) above their glass transition temperature, then blown using high pressure air into bottles using metal blow moulds. The preform is always stretched with a core rod as part of the process. In the single-stage process both preform manufacture and bottle blowing are performed in the same machine. The stretching of some polymers, such as PET (polyethylene terephthalate) results in strain hardening of the resin, allowing the bottles to resist deforming under the pressures formed by carbonated beverages, which typically approach 60 psi.The main applications are bottles, jars and other containers.

Advantages of blow moulding include: low tool and die cost; fast production rates; ability to mould complex part; produces recyclable parts.

Disadvantages of blow moulding include: limited to hollow parts, wall thickness is hard to control.