Tube extrusion

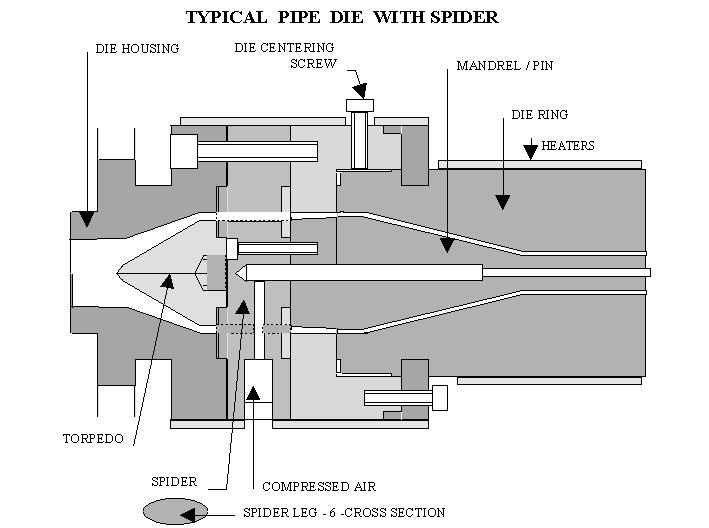

Tube extrusion is one of many extrusion techniques. The technique uses slightly different mould or die to extrude hollow shapes. Tubes and hollow sections are typically extruded through a die that determines the outer shape, and a mandrel, located in the aperture of the die, determines the inside shape and section thickness. Material is forced around the mandrel through several entry ports (depends on type of mould) after which it recombines with the rest of the material surrounding the mandrel. It is important to manage temperatures well inside the mould. If temperatures are to low, the material won't recombine for 100%. If temperatures are not constant the viscosity of the material will constantly change and influence the process.